- Hydraulic Guillotine Shearing Machine

Hydraulic guillotine shearing machine, also known as hydraulic guillotine type plate shearer, adopts framework structure for all-steel welding. With high precision and good rigidity, this hydraulic shearing machine adopts hydraulic preload. The hydraulic system uses two-way cartridge integrated valve. The whole system adopts PLC programmable controller. The machine can be equipped with stroke digital display...

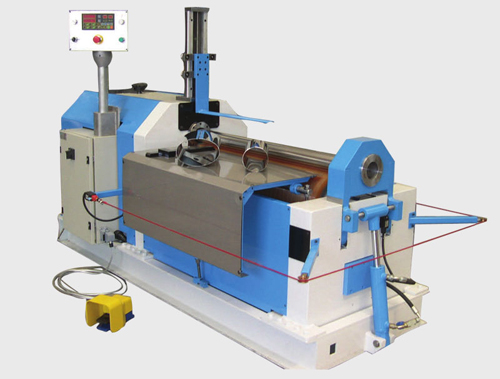

- Hydraulic Pendulum Shearing Machine

Hydraulic pendulum shearing machine is also known as hydraulic pendulum plate shearing machine, hydraulic swing type plate shear or hydraulic swing beam shearing machine. The hydraulic shearing machine adopts integral welded steel plate structure, hydraulic upper transmission and vibration to eliminate stress. This machine is famous for high strength and good rigidity...

Description

Hydraulic shearing machine makes use of movable upper blade, fixed lower blade and reasonable blade gap to apply shearing force to sheet metals of different thickness. The machine employs hydraulically-driven swing beam, the steel plate welded structure and accumulator-based pullback cylinder with steady and reliable operation. It is equipped with lighting alignment device. Our rich industry experience allows HB to offer these hydraulic steel plate shearers in customized specifications so as to meet clients' specific requirements. Further, this hydraulic shearing machine is simple to operate. This hydraulic plate shearing machine comes with most hold-down and shearing capabilities than any other industrial shear machines available in the market.

Operation

- Before empty running test, use the artificial disc car first. After ensuring normal state, operators can start the hydraulic steel plate shearer or hydraulic shearing machine.

- Check oil in the oil tank is sufficient or not. After starting the oil pump, check whether there are valve or piping leakage. Pressure should be consistent with the requirements. Purge valve should be opened to release the air from the system.

Maintenance

- The hydraulic steel plate shearer or hydraulic shearing machine should be operated in strict accordance with rules.

- Before starting the machine, lubricate the machine timely with fixed amount according to the lubrication chart. The oil should be cleaned and free of precipitation.

- The machine tool of this hydraulic plate shearing machine must always be kept clean and tidy.

- Change the lubrication oil in the motor bearing frequently. We should also check whether the hydraulic shearing machine's electrical part works normally, safely and reliably or not.

- Lubricate and clean the hydraulic steel plate shearer ten minutes before getting off work every day.

- Regularly check the V-belt, handle, knob and button are damaged or not. If it is badly worn, it should be replaced promptly. Besides, we should prepare some spare parts for supplement.

- Check and repair switches and handle regularly to ensure that its work is reliable.

- Unauthorized persons are prohibited to operate this machine. It is usually required that the hydraulic shearing machine (hydraulic steel plate shearer) must be stopped as soon as the operator leaves.

Lanteky® Machine is a professional manufacturer and supplier of hydraulic plate shearing machines in China. In addition, we also provide plate rolling machine, cut-to-length line, leveling machine, press brake, profile bending machine, etc. Due to our products' high quality, professional service and competitive price, our hydraulic shearing machines are well received by customers all over the world.